Epiroc are an alternative to hydraulic breakers by generating higher productivity in several applications. Designed to achieve optimum performance and precision when removing materials. Offers low noise and less vibration; critical when working in sensitive environments. Epiroc consist of extremely robust spur gears driven by high torque hydraulic motors for the most challenging conditions with little to no risk of failure.

Drum Cutter Transverse & Longitudinal

Adding Value To Your

Excavator: SPECIFICALLY DESIGNED FOR GRINDING ROCK, CONCRETE & WOOD

Rotary drum cutters or rock cutters are hydraulic excavator attachments. Designed to increase the range of work available to excavators and increase their return on investment.

- Tunnelling

- Trenching

- Demolition

- Refurbishment

- Quarrying

- Foundation work

- Under water excavations

- Forestry clearance

- Soil mixing

- Slag removal in steel industry

How to choose the correct size rock cutter for my excavator?

- Matching the correct size rock cutter with the excavator is important. The rock cutter must be strong enough to take the weight of the excavator and the excavator must be strong enough to take the energy transmitted back into the machine from the drum cutter.

- The weight of the rock cutter must not destabilize the excavator. Rock cutters get their power from the hydraulic flow and pressure from the excavator. Best cutting performance is achieved when the hydraulic motor in the drum cutter matches the hydraulic output from the excavator’s pumps.

MOTOR SIZES e.g. ER 250-2, ER 250-3, etc

By changing the cam ring in the hydraulic motor from an ER 250-2 to an ER 250-3 for example, the volume of oil per revolution of the hydraulic motor is increased. This increases the power required per revolution which translates into higher torque and higher productivity. In this way, the hydraulic motor in the drum cutter is matched to obtain the optimum performance from the pumps in the excavator.

Nothing can be gained by selecting a rock cutter fitted with a hydraulic motor that requires 190 l/min of oil to obtain maximum performance when the excavator can only supply 150 l/min!!!

The time required to convert a motor from one size to another is approx. 1 hour.

1 or 2 Pump Availability

The majority of excavators are fitted with two pumps. As an example, the 17 ton CASE CX 160 has 2 x 136.7 l/min pumps. The primary function of one pump is to drive the main functions of the excavator and the second provides oil for the attachments.

The ER 600 rock cutter is the ideal size for this excavator but the ER 600-1 motor requires 120 l/min and the ER 600-2 motor requires 150 l/min.

If the oil flow from only one pump is available then the -1 motor size is correct but if the pumps are connected so that they can both provide flow for the attachment, then the -2 motor can be used.

Operating limits in terms of rock hardness for drum cutters

Power is required to fracture material such as concrete or rock. As the compressible strength of the material increases, more power is required to fracture it. The power available from the drum cutter is limited by the hydraulic motor and the power available from the excavator. As drum cutters increase in size, they have larger hydraulic motors, take more power from the excavator and are capable of cutting harder rocks.

Please see the Compressive Strength Table for Common Rock Types in the box below to see the operating limits for each size of drum cutter. This table is intended as a guide and in some conditions, these limits can vary.

What production rate can I expect from a drum cutter?

The Productivity Table in the downloads below is an indicator of the productivity rates that can be achieved within the operating range of rock hardness suitable for rotary drum cutters. These levels can vary by as much as plus/minus 15% depending on:

- Size of hydraulic motor.

- Cutting direction (wall, floor, trench, etc).

- Operator experience.

- Ground conditions e.g. layers, fissures, weathering, etc.

Transverse Specs

| Model | Excavator Tons | Rotation Speed RPM | Oil flow @725 psi gal/min | Torq @3000 psi lbf-ft | Torq @5000 psi lbf-ft | Cutting Force @3000 psi lbf | Cutting Force @5000 psi lbf | Weight lbs |

|---|---|---|---|---|---|---|---|---|

| ER 50 | 1 – 3 | 150 | 6.6 – 10.0 | 423 – 628 | 706 – 1047 | 1147 – 1700 | 1912 – 2835 | 220 |

| ER 100 | 3 – 7 | 110 | 10.8 – 16.4 | 925 – 1378 | 1548 – 8615 | 1763 – 2625 | 2950 – 4376 | 485 |

| ER 250 | 7 – 15 | 90 – 95 | 15.8 – 24.4 | – | 2581 – 3835 | – | 3934 – 5854 | 992 |

| ER 600 | 10 – 20 | 80 | 31.7 – 39.6 | – | 6396 – 7670 | – | 9780 – 11670 | 1980 |

| ER 650 | 10 – 20 | 80 – 85 | 37.0 – 50.2 | – | 23088 – 34120 | – | 7037 – 10400 | 2200 |

| ER 1200 | 20 – 40 | 75 | 47.5 – 79.2 | – | 10000 – 17250 | – | 9400 – 16190 | 3500 |

| ER 1500 | 20 – 40 | 75 | 47.5 – 79.2 | – | 10000 – 17250 | – | 9400 – 16190 | 3640 – 3860 |

| ER 2000 | 30 – 50 | 65 – 75 | 79.2 – 103 | – | 16450 – 24700 | – | 14740 – 22150 | 4850 |

| ER 3000 | 45 – 70 | 53 – 62 | 92.5 – 118.9 | – | 22990 – 34585 | – | 17410 – 26190 | 7275 |

| ER 5500 | 70 – 125 | 48 – 52 | 185 – 250 | – | 54800 – 80500 | – | 36330 – 53330 | 13200 |

Profile Cutter Specs

| Model | Excavator Weight (tons) | Cutting Head Diameter (mm) | Cutting Head Width (mm) | Weight (kg) | Number of Picks (pcs) |

|---|---|---|---|---|---|

| ER 250 P | 7 – 15 | 400 | 800 | 550 | 80 |

| ER 650 P | 15 – 25 | 540 | 1,070 | 1,300 | 90 |

| ER 1500 P | 25 – 30 | 650 | 1,200 | 1,900 | 80 |

Tunneling Cutter Specs

| Model | Excavator Weight (ton) | Cutting Head Diameter (mm) | Cutting Head Width (mm) | Weight (kg) | Number of Picks (pcs) |

|---|---|---|---|---|---|

| ER 650 T | 15 – 25 | 600 | 1,000 | 1,250 | 70 |

| ER 1500 T | 20 – 40 | 750 | 1,500 | 2,200 | 72 |

| ER 2000 T | 30 – 50 | 750 | 1,560 | 2,800 | 72 |

SPEC Carriers for Drumcutters ER 650 to ER 5500

| ER Range | – | ER 650 | ER 1500X | ER 1500XL | ER 1700 | ER 2000 | ER 3000 | ER 5500 |

| CATERPILLAR Carriers | – | 320, 323, 325 | 320, 323, 325, 326, 330, 336 | 320, 323, 325, 326, 330, 336 | 326, 330, 336 | 336, 349 | 349, 352 | 374, 385, 390 CALL FIRST |

| Carrier weight class 1 | t | 15 – 28 | 20 – 40 | 20 – 40 | 30 – 50 | 35 – 50 | 50 – 70 | 70 – 125 |

| Service weight 2 | lbs | 2645 | 4409 | 4630 | 5401 | 6393 | 8818 | 15432 |

| Product weight | lbs | 2205 | 3858 | 4079 | 4850 | 5732 | 7715 | 13228 |

| Nominal power | hp | 109 | 163 | 163 | 163 | 218 | 272 | 544 |

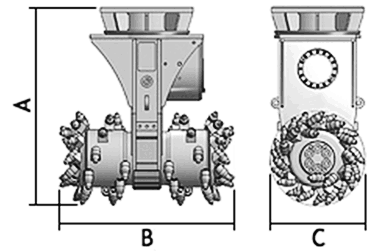

| A | inches | 47 | 56 | 56 | 56.3 | 62 | 65 | 77.5 |

| B | inches | 31.5 | 35 | 39 | 41 | 49 | 52.4 | 63 |

| C | Inches | 22.6 | 26.4 | 26.4 | 26.8 | 28.3 | 31.7 | 36.3 |

| Rotational speed | rpm | 80 | 75 | 75 | 72 | 65 | 53 | 48 |

| Optimum oil flow 3 | gpm | 37 – 50 | 54 – 79 | 54 – 79 | 77 – 95 | 79 – 103 | 92 – 119 | 185 – 251 |

| Maximum torque 4 | Nm | 12400 | 23400 | 23400 | 27900 | 31500 | 46800 | 111500 |

| Maximum cutting force 4 | N | 42400 | 65000 | 65000 | 77500 | 87500 | 116300 | 242400 |

| Pick shaft diameter | mm | 30 | 30 | 30 | 30 | 30 | 38-30 | 38 |

| Number of picks | pcs | 44 | 44 | 48 | 56 | 56 | 64 | 68 |

| Maximum oil flow 5 | gpm | 55 | 85 | 85 | 106 | 108 | 132 | 264 |

| Maximum operating pressure | bar | 350 | 350 | 350 | 350 | 350 | 350 | 350 |

| Rock strength | – | 8,700 | 11,600 | 11,600 | 14,500 | 14,500 | 18,850 | 24,600 |

Drum Cutter ER 1700

The ER 1700 is an ER 1500 XL HD fitted with larger displacement hydraulic motors. When installed on excavators with enough oil flow, the extra torque translates into more productivity.

The double head drum cutter is ideally suited for trenching, tunneling, foundation work demolition and soil mixing. Their operating characteristics allow them to be used in noise and vibration sensitive areas.

Features

- High displacement motors with high torque for extra productivity and cutting force.

- Gear box manufactured from thicker steel plate.

- Stronger output shaft fixing to the gear box housing.

- Thicker wear plates.

Technical Data of ER1700

| – | UNITS | ER 1700-1 | ER 1700-3 |

| Recommended RPM | RPM | 72 | 72 |

| Recommended oil flow | GPM (l/min) | 76.6 (290) | 95.1 (360) |

| Maximum oil flow | GPM (l/min) | 95.1 (360) | 105.7 (400) |

| Max. operating oil pressure | psi (bar) | 5,500 (380) | 5,500 (380) |

| Torque at 5,500 psi (380 bar) | lbf‐ft (KNm) | 18,660 (25.3) | 22,350 (30.3) |

| Cutting force at 5,500 psi (380 bar) | lbf (N) | 16,725 (74.4) | 20,030 (89.1) |

HYDRAULIC HOSE FITTINGS: Pressure & return: JIC ‐16 Case drain: JIC‐12

| Length of drum cutter (A) | 56.0 in (1,420 mm) |

| Width of cutter head (B) | 41.00 in (1,040 mm) |

| Diameter of cutter head (C) | 26,75 in (680 mm) |

| Number of picks | 56 |

| Standard picks | ER 19/75/70/30 Q |

| Weight | 4,850 lbs. (2,200 kg) |